Antiseptic thermoplastic polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

introduction

In highway engineering, excellent anti-corrosion technology is a key factor in ensuring the long-term stable operation of infrastructure. This paper focuses on the technical requirements and relevant inspection methods of anti-corrosion thermoplastic polyvinyl chloride (PVC) powder coatings and coatings for highway. By gaining an in-depth understanding of this standard specification, we will reveal the importance of its application in highway engineering and how to ensure its quality and reliability.

Technical requirement

Coating adhesion

The standard specifies the adhesion test method for powder coatings to ensure that the coating adheres tightly to the surface of the substrate. Good adhesion can not only improve the stability of the coating, but also enhance its corrosion resistance and extend its service life.

Weather resistance

The road environment is complex, and the coating needs to have excellent weather resistance, and can resist external adverse factors such as sun and rain, temperature changes. The development of relevant test methods is helpful to evaluate the performance of coatings under different climatic conditions.

Chemical stability

Considering the effects of chemical corrosion on the road, the chemical stability of the paint is particularly critical. The standard specifies testing methods to ensure that coatings remain stable in the face of chemicals such as acids and bases.

Antiseptic thermoplastic polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

Inspection method

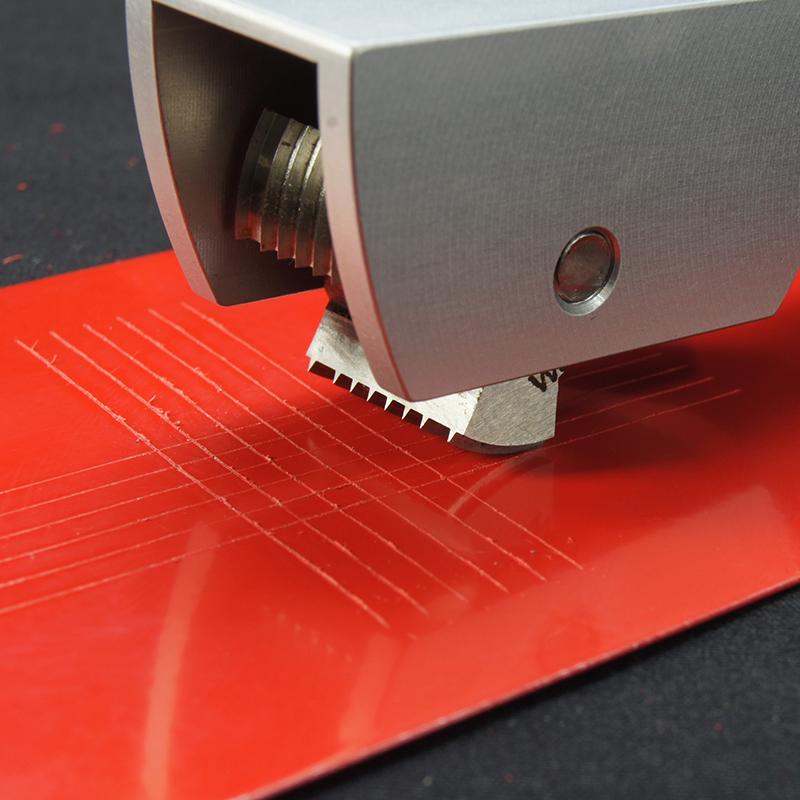

1. Adhesion test

The adhesion test usually uses the scratch or peel method to evaluate the adhesion of the coating by judging the condition of the scratch or peel. This test method is designed to simulate the physical stimuli that may be faced under actual conditions of use, ensuring that the coating will remain stable under a variety of stresses.

2. Weather resistance test

Weather resistance tests often include tests such as exposure to sunlight and salt spray to simulate the effects of different climatic conditions. By evaluating the coating’s performance under these conditions, it is possible to better understand its actual durability in highway environments.

3. Chemical stability test

The chemical stability test mainly focuses on the performance of the coating in chemical environments such as acid and alkali. The purpose of this test is to verify that the coating can maintain its performance in the face of possible chemical corrosion.

Antiseptic thermoplastic polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

Future development trend

The establishment of the standard of anti-corrosion thermoplastic polyvinyl chloride (PVC) powder coating for highway is aimed at regulating the production and application of the coating and improving its reliability in highway engineering. As technology continues to advance, future trends may include more stringent environmental adaptability testing, more efficient production processes, and more environmentally friendly raw material selection.

conclusion

Through the detailed analysis of the technical requirements and inspection methods of the standard of anti-corrosion thermoplastic polyvinyl chloride (PVC) powder coating for highway, we have a deeper understanding of the application of this key technology in highway engineering. The formulation of standards not only helps to ensure the quality and performance of coatings, but also provides strong support for the sustainable development of highway engineering. In the future, with the continuous innovation of technology, we are expected to witness the application of more advanced and environmentally friendly anti-corrosion coatings in highway engineering, providing a more reliable guarantee for the long-term stable operation of infrastructure.