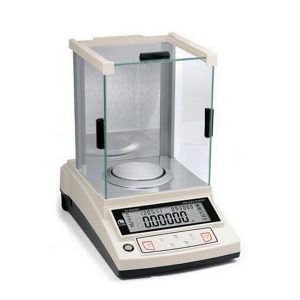

JWG-64AS Medicine Liquid Intelligent Particle Detector

- Description

- Inquiry

Description

JWG-64AS Medicine Liquid Intelligent Particle Detector

Performance characteristics:

l Meet the 2020 edition of “Chinese Pharmacopoeia” can directly detect the insoluble particle content and size of injection, aseptic powder, infusion equipment, filtration rate, drug packaging anesthesia equipment, etc

l Adopt high-performance imported laser light source and compensation circuit to ensure the test accuracy of various colorless and colored samples, and can directly detect electrolyte-free samples

l Adopt the imported high-pressure injection pump sampling system, which can be set according to the sample variety tested, with high injection accuracy, meet the detection requirements of high-viscosity samples, and is not affected by geographical location and other factors, and meet the requirements of different altitudes.

Import 316L and imported PTFE materials are used in the injection slit and pipeline, which can directly detect special solutions such as organic solvents and oil substrates.

l Different high-pressure injection systems can be replaced according to the needs of the injection volume

l With pharmacopeia standard infusion test, the number of tests can be arbitrarily set

l There is a special test procedure for small-volume injection (small injection), which can be injected according to the specifications of small injection, and automatically converted into the size and quantity of container particles after the test is completed, which meets the requirements of Chinese Pharmacopoeia and international general requirements.

l Detection of particulate content in anaesthesia kits

l Filter rate detection of precision filters

l GB8368-2005 Detection of particulate pollution

l GB8368-2018 Detection of particulate pollution

l Particle content detection of drug packaging materials

l Full channel test (better than the pharmacopoeia for instrument calibration requirements)

l Screw glass agitator, uniform speed adjustable, at any time to grasp the mixing speed, to ensure that the particles in the container uniform type. Improve data accuracy

l Automatic data processing, a variety of printing modes to meet different printing needs

l with automatic data transmission computer function; It can access the laboratory operating platform for management, and special data analysis software for data preservation and statistics.

l Level 4 rights management

l Can reach 1000 operators management

l With data retrieval function, at any time to retrieve historical data and operational behavior

l can provide 3Q certification and documentation

l With audit trail function (including software and computer)

l Audit trail software is counter-control function software.

Parameters:

■ Channel setting: 64 channels, thousands of particle sizes can be customized, accuracy 0.1µm

■ Test range: 1~500µm(segment sensor required)

■ Technique range: 0~9999999 grains

■ Sample volume: 0.2ml~1000ml(accuracy 0.1ml)

■ Sample volume accuracy: < Plus or minus 0.5% (0.2 ml to 1000 ml)

■ Syringe volume: 10ml, 25ml optional

■ Injection speed: 2~100ml/min, any setting

■ Counting accuracy: < Specified value ±5%

■ Channel resolution: > 95%

■ Relative standard deviation: RSD< 1.5% (Standard particle ≥1000 particles /ml)

■ Optimal detection concentration: 0~18000 granules /ml

■ Mixing speed: 0~2000 RPM, adjustable rotary pulp

■ Working temperature: 10~40℃

■ Power supply: AC220V ±10%; 50Hz; < 80W

■ Data output: computer controlled instrument, built-in needle micro printer