LR-QBPL-5000N Fatigue testing machine

- Description

- Inquiry

Description

Fatigue testing machine

Product introduction

The test bench adopts servo motor drive technology, and the vertical loading system adopts electric cylinder to apply force, which can do dynamic fatigue test and static performance test of various parts. Equipped with professional testing software can realize the load, deformation test, can display the whole process of the test curve. The test of this system realizes accurate closed-loop control and electronic fatigue test. The test bench is powerful and easy to operate.

Fatigue testing machine

Scheme description

Host:

The testing machine is composed of double column structure, control system, test system, strong current system and accessories.

The loading mechanism of the testing machine uses a servo electric cylinder controlled by servo closed-loop with high reliability and high performance. The electric cylinder converts the rotating motion of the servo motor into the linear motion of the push rod through the mechanical motion of the lead screw and the lead screw pair. With the closed-loop control characteristic of servo motor, the precise control of thrust, speed and position can be realized easily. Using modern motion control technology, numerical control technology and bus (network) technology, the program and bus (network) control is realized. Because of its easy control and use, it will realize the precision motion control that the cylinder and hydraulic cylinder drive can not achieve. The electric cylinder for loading is mounted on the beam, which rotates the lead screw by a rotating wheel, thus adjusting the test space.

Electric cylinder selection servo motor, precision ball screw, perfect function, advanced performance, reliable use. The specific structure is as follows: (Working principle diagram and configuration diagram are as follows)

Fatigue testing machine

| Type | Linear Type | |

| Effective travel(mm) | 200(Up to 5KN) | |

| Lead of the screw(nun) | 32mm | ball screw |

| Dynamic condition | Frequency: 0.1 ~ 1.24Hz Load: 5kN | |

| Dynamic output(kn〉 | 5 | |

| Rated power of motor(kw) | 3 | |

| Rated motor speed(rpm) | 1500 | |

| Encoder type | incremental

| |

| Internal anti-turning mechanism | Have | |

| Limit switch | have | Four, NPN. Usually closed |

| Using temperature range | Room normal temperature | |

| Installation method | front barrel flange | |

| Type | Linear Type | |

| Effective travel(mm) | 200(Up to 5KN) | |

| Lead of the screw(nun) | 32mm | ball screw |

| Dynamic condition | Frequency: 0.1 ~ 1.24Hz Load: 5kN | |

| Dynamic output(kn〉 | 5 | |

| Rated power of motor(kw) | 3 | |

| Rated motor speed(rpm) | 1500 | |

| Encoder type | incremental

| |

| Internal anti-turning mechanism | Have | |

| Limit switch | have | Four, NPN. Usually closed |

| Using temperature range | Room normal temperature | |

| Installation method | front barrel flange |

Fatigue testing machine

2.Electrical Appliances and software:

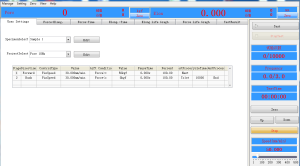

The microcomputer measurement and control system is composed of special control board, computer, servo drive unit, software, control cabinet, etc. developed by our company to complete the control of the whole test process. Real-time display of various test parameters. Computer data system using Windows operating software, Chinese interface, screen display of various test parameters and test curves, can be convenient for data storage, analysis and printing.

The software has force and displacement protection function, and the software protection should be set before the test. When force is controlled, set displacement protection. When displacement is controlled, force protection is set.

Equipped with strong current control cabinet, control cabinet with servo motor driver and strong current unit.