- Description

- Inquiry

Description

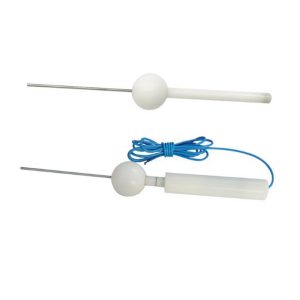

Spring impact hammer component

Basic introduction:

The spring impact hammer calibration device is a laboratory special device, mainly used for the calibration of the spring impact hammer, it is designed and manufactured according to IEC60068-2-75-1997 and GB2423.55-2006 standards, mainly suitable for third-party testing institutions, national Exit and Entry Administration departments and electrical related research institutes.

All parts of the spring impact hammer calibration device are manufactured according to the dimensional tolerance requirements of IEC60068-2-75 Appendix B normative document, and most of the key parts are processed by special materials and special processes, with superior performance in accuracy and stability. The device adopts a single weight design to avoid the uncertainty caused by the replacement of weights, and supports the calibration of most spring impact hammer from all manufacturers at home and abroad. If it is necessary to meet the spring impact hammer calibration needs of German PTL company 2J, special guide is added.

Spring impact hammer component

| Similar product | Similar product | |

| Actual accuracy | 0.01J | 0.02J |

| Repeatability | ±0.01J | 0.02-0.04J |

| Maximum range | 0-2.2J | 0.1-2J |

| Guide groove Outer diameter | 51mm | 51mm |

| Swing rod energy loss * | <0.002j | <0.008J |

| Trigger travel* | >30mm | <18mm |

| Counterweight* | 1 piece | 2piece |

Spring impact hammer component

Installation of device

1.Working environment: dust, humidity: 18-32°C, humidity: 50%-70%RH is appropriate.

2.Install a smooth horizontal platform.

3.Adjust the four supporting feet so that the instrument is in a horizontal state.

4.Side away from wall > 1 meter

How to use the device:

- When the pendulum is at rest, the pointer should be close to the pendulum, and the pointer should be zero.

- Install the spring impact hammer in the guide slot position, and make the spring impact hammer in the trigger state.

- Shake the release wheel until the spring impact hammer is triggered, and quickly catch the falling pendulum rod to prevent impact.

- or the relevant principles, refer to the relevant standards.

Read the dial value. Due to the principle limitation of the device, the value of the dial edge is the measured value. Note when using:

Note when using:- The pointer can be triggered by zero and the pendulum bar is stationary to obtain better measured values.

- The average of the spring impact hammer is taken for odd times at the same position. Pay attention to changing the Angle during the test.

Device adjustment method:

- Change the weight position.

- Change the tension of the wool damper. (Use with caution for non-professionals)

Maintenance of the device:

- Use absorbent cotton with alcohol or anti-rust oil or wax fragrance to wipe the body.

- Avoid moving the device as much as possible to avoid external vibration and impact.

- The pendulum rod motion mechanism needs to be re-calibrated after lubricating oil filling.

- The wool damper should be carefully adjusted and re-calibrated after adjustment.