LRGD-5 Vacuum Plasma Cleaner

- Description

- Inquiry

Description

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

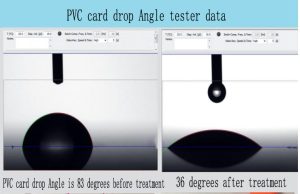

Activated surfaceImprove the hydrophilicity of the product

Improve product surface adhesion

Processing before printing and bonding

Environmental protection technology, low temperature plasma, increase printing, dispensing, coating and other bonding effect

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

Product Features

GD-5 plasma cleaner, PLC+ touch screen control, widely used in plasma cleaning, etching, plasma coating, plasma activation and surface modification and other occasions. Through its treatment, it can improve the wetting ability of materials, so that a variety of materials can be coated, plated and other operations, enhance the adhesion force, bonding force, and remove organic pollutants, oil or grease.

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

Plasma application horizon

Electronic glass, printing jet code, plastic rubber, electronic packaging

Packaging industry

Professional to improve the film paper, glazed paper, polished, gold and silver card, aluminum plated paper, UV, OPP, PP, PE and other color boxes, color box surface paste box fastness;

Electronic industry

Electronic components processing plasma pretreatment, PCB cleaning, removal of static electricity, LED support, IC surface cleaning and bonding.

Automobile industry

Plasma surface pretreatment process is adopted for car headlight bonding, brake pad, wiper, hood, instrument and bumper;

Printing code industry

Plasma pretreatment before pad printing, screen printing and jet coding on the surface of composite materials such as plastic, metal and boyao can improve the adhesion of material surface to ink

Precision glass

All kinds of precision glass, spraying, printing, bonding before treatment. LCD IC binding before the terminal surface cleaning, improve the glass surface cleanliness and hydrophilicity:

Plastic industry

Plastic, rubber, gold and other pretreatment before bonding, improve the surface adhesion; · Pretreat the plastic shell of mobile phones, computers, toys and so on before painting to improve the surface adhesion

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

Aviation industry

Plasma cleaning applications

With the development of the aviation industry, manufacturers will be looking for products with longer life, more reliable quality and lower cost. Previously, aircraft masks and strips were made of aluminum alloy, but now, these parts are mainly made of carbon fiber reinforced plastics. Plasmas play a big role in this. Carbon fiber reinforced plastic surface stability is better, so that the bonding and spraying process presented a more perfect state

Metal industry

(Whether it’s the metal accessories we wear or the metal tables and chairs we use in our homes, they may all have plasma treated surfaces. Nowadays, people are becoming more and more sophisticated in product design. Manufacturers in order to meet the needs of consumers will produce a variety of beautiful and durable metal products to attract the market, it can be said that plasma surface treatment of materials has infiltrated into our lives, in the past 30 years, low temperature plasma is widely used to change the mechanical properties of the surface of metal materials, plasma surface treatment of metal is :1. The friction and corrosion resistance of iron and steel alloys can be improved by ion beam nitrizing. 2. When ions are injected into metal surface, metal solid solution and sediment can be formed, so the hardness and wear of metal materials can be improved

Medical industry

Medical materials refer to inanimate materials used in contact with biological tissues to form functions. They are very good auxiliary materials in medical treatment, including polymer materials, metals, ceramics, glass or composite of various materials, etc., which are widely used in artificial organs, surgical repair, dental materials, cladding materials, orthopedic devices and medicine. Functional and mechanical properties, these materials are very good, but good biocompatibility is also quite critical, using plasma surface modification method can make them good compatibility, plasma only on the surface of a thin layer of treatment, does not change the performance of the material, and sterilization effect. So plasma surface treatment is becoming more and more widely used in medical materials.

Household appliance industry

Surface coating, spraying and bonding processes of daily necessities and household appliances. Plasma pretreatment can improve the bonding and coating quality of products

Plastic industry

Plastic, rubber, metal and other pretreatment before bonding, improve the surface adhesion, mobile phones, computers, toys and other plastic shell spray pretreatment, improve the surface adhesion

Packaging industry

In the field of printing and packaging applications, perhaps in the plasma surface treatment before what is not much known to the public, in fact, we very early began to use corona discharge, flame treatment surface modification method, that is, the most common form of discharge in the ionosome – dielectric barrier discharge (DBD) but now low temperature plasma processor has been widely used in the packaging industry, Change the printability of the packaging surface and the adhesion of the composite surface, plasma processing function for UV, coating, glazing, polymer and other materials surface treatment; Professional improve coated paper, glazed paper polishing, gold and silver card, aluminum plated paper, UV, OPP, PP, PET and other color boxes, color box surface paste box fastness; Eliminate all kinds of packaging box opening problem. Improve work efficiency, reduce grinding pollution, eliminate paper powder pollution of box paste machine, save consumables, save glue cost

Photoelectric glass and electronic industry applications

All kinds of glass surface cleaning, improve the glass surface hydrophilicity, optimize the plating, printing, bonding and spraying technology;

@ Flexible and non-flexible printed circuit board contact cleaning, LED fluorescent lamp “contact” cleaning and improve the surface adhesive firmness;

Precision glass

@ Electronic components, PCB cleaning, IC surface cleaning, activation enhancement binding, etc.; @LCD LCD screen terminal surface before plasma cleaning;

Electronic industry

Electronic components processing of plasma pretreatment, PCB cleaning, electrostatic removal, LED support, IC surface cleaning and bonding

Automobile industry

EPDM rubber strip spray lubrication coating or flocking glue pretreatment process; Plasma surface pretreatment technology is used for car headlight bonding, brake pad wiper, hood, instrument and bumper

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

plasma cleaner (plasma cleaner), also known as plasma surface treatment instrument, is a new high-tech technology, the use of plasma to achieve the conventional cleaning method can not achieve the effect

Plasma cleaning machine has the following nine advantages:

First, the cleaning object is dry after plasma cleaning, and it can be sent to the next process without drying. Can be the processing efficiency of the whole process line;

Two, plasma cleaning machine enables users to stay away from harmful solvents to harm the human body, but also avoid the problem of wet cleaning is easy to wash the cleaning object;

Three, avoid the use of trichloroethane and other harmful solvents, so that there will be no harmful pollutants after cleaning, so this cleaning method belongs to the environmental protection of the green cleaning method. This becomes more and more important in the context of global concern for environmental protection;

Fourth, the plasma generated by the high frequency of the radio wave range is different from the direct light such as laser. Plasma is not very directional, which allows it to reach deep into the tiny holes and dents of an object to complete its cleaning task without much concern for the shape of the object being cleaned. And the cleaning effect of these hard-to-clean parts is even better than that of freon cleaning;

Five, the use of plasma cleaning machine, can make the cleaning efficiency can be greatly improved. The whole cleaning process can be completed in a few minutes, so it has the characteristics of high yield;

Six, plasma cleaning need to control the vacuum degree is about 100Pa, this cleaning condition is easy to achieve. Therefore, the equipment cost of this device is not high, and the cleaning process does not require the use of more expensive organic solvents, which makes the overall cost lower than the traditional wet cleaning process;

Seven, the use of plasma cleaning machine, avoid the cleaning liquid transportation, storage, discharge and other treatment measures, so the production site is easy to keep clean and sanitary;

Eight, plasma cleaning machine can be regardless of the treatment of objects, it can deal with a variety of materials, whether it is metal, semiconductor, oxide, or polymer materials (such as polypropylene, polyvinyl chloride, polytetrafluoroethylene, polyimide, polyester, epoxy resin and other polymers) can be used to deal with plasma. Therefore, it is especially suitable for materials that are not heat resistant and solvent resistant. It can also selectively clean the whole, part or complex structure of the material;

Nine, in the completion of cleaning decontamination at the same time, but also can improve the surface performance of the material itself. Such as improving the wettability of the surface, improving the adhesion of the film, etc., which is very important in many applications.

1. What does plasma surface processor (cleaning machine) do?

Plasma surface processor uses current to generate normal temperature plasma to act on the tongue surface of various packaging such as toothpaste box, cigarette box, wine box and gift box. After processing and gluing, there will be no ungluing problem, and you can paste the box with ordinary glue, greatly reducing the cost of glue.

Is your company using a fully automatic box paste machine? The plasma surface processor can be used together with the box paste machine.

What are the products of plasma surface processor?

A: Currently on the market is the common single nozzle plasma surface processor. And our company has developed a number of products such as double nozzle, three nozzle, rotating nozzle, etc. Our professional R & D team can also specialize in R & D and production according to customers’ needs.

Main functions and advantages of plasma surface processor?

A: 1. Spray plasma flow is neutral, can be a variety of polymer, glass, metal, semiconductor, rubber, PCB circuit board and other materials for surface treatment.

2. Plasma surface processor after treatment to remove hydrogen carbide dirt, such as grease, auxiliary additives, is conducive to bonding, durable and stable performance, long retention time.

3 plasma temperature is high and low, for different materials to choose different temperature plasma, (power size can be adjusted) suitable for those surface materials sensitive to temperature products.

4. Every type of atmospheric pressure equipment has on-line function! Can be directly installed on the production line, with field equipment online operation processing! Relative to the reverse operation of edging machine, greatly improve the work efficiency.

5. Only air and electricity are consumed, so the operation cost is low and the operation is safer.

6. Dry method treatment without pollution, no waste water, meet the requirements of environmental protection; And replace the traditional edging machine, put an end to the impact of paper powder paper wool on the environment and equipment.

7. After plasma surface processor treatment, ordinary glue can be used to stick the box, reducing the production cost. Plasma processor introduction: plasma technology is a good solution to the coated paper, glazing paper, coated paper, aluminum plated paper, UV coating, PP, PET and other materials bonding is not strong, or unable to bond the problem. To solve the problem that many enterprises used to use the traditional local coating, local glazing, surface grinding or cutting paste line, the use of special glue to improve the bonding method.

Plasma technology after the use of ordinary water-based glue can be very good bonding, no longer because of different cardboard and replace different glue. Not only effectively solve the paste box, paste box production process problems, but also have a good guarantee for the enterprise’s process, efficiency, quality.

Selective surface modification can be achieved by plasma processing:

1. Activation: greatly improve the wettability of the surface, forming an active surface

2. Cleaning: Remove dust and oil, fine cleaning and electrostatic removal

3. Coating: A functional surface is provided by a surface coating treatment

4. Improve the adhesion ability of the surface

5. Improve the reliability and durability of surface bonding

Vacuum plasma cleaner,Research small plasma cleaning machine,University laboratory plasma cleaner

5. Application Field:

All kinds of glass surface cleaning, improve the glass surface hydrophilicity, optimize the glass coating, printing, bonding and spraying technology;

Flexible and non-flexible printed circuit board contact cleaning, LED fluorescent lamp “contact” cleaning and improve the surface adhesive firmness;

Electronic components, PCB cleaning, IC surface cleaning, activation enhancement binding, etc.;

Plasma cleaning before LCD terminal lamination;

Automotive industry application

Automotive EPDM seal strip, flocking and pre-coating pretreatment instead of using base coating;

Car lamp base, groove, brake pad, bumper bonding, plasma pretreatment before spraying;

Pre-treatment of automobile anti-puncture tire before gluing;

New energy vehicle lithium battery electrode plate welding, coating surface activation, cleaning, etc.;

Plastics industry application

PP, PVC, PET, PC, PE, PTFE and other types of plastic materials spraying, printing, electroplating, bonding and flocking before treatment.

All kinds of plastic, silicone, rubber, metal and other materials spraying, printing, electroplating, bonding before surface modification, removal of surface pollutants;

Mobile phones, computers, toys and other plastic shell printing, spray pretreatment, improve surface adhesion;

Plastic cosmetic bottle preprocessing before printing, improve the surface adhesion can prevent word falling off and improve product quality;

Packaging industry application

Professional improve coated paper, glazing paper, polishing, gold and silver card, aluminum plated paper, UV, OPP, PP, PET and other color boxes, color box surface paste box fastness;

Plasma pretreatment of milk powder cans and beverage cans before welding;

Printing and coding industry applications

Plasma pretreatment before pad printing, screen printing and jet coding on the surface of plastic, metal, glass and other composite materials to improve the adhesion of material surface to ink;

PE, PTFE, silicone rubber wire and cable coding before processing;

PVC, PET, ABS smart card pre-processing;

Appliance industry application

Plasma activation before coating, spraying and bonding of daily necessities and household appliances can improve the surface adhesion and bonding force of products.

Health pot heating plate plasma cleaning enhanced glue adhesion, firmness, etc.;