LR-C010 High speed stripping strength tester

- Description

- Inquiry

Description

Ring Crush Tester

Introduction

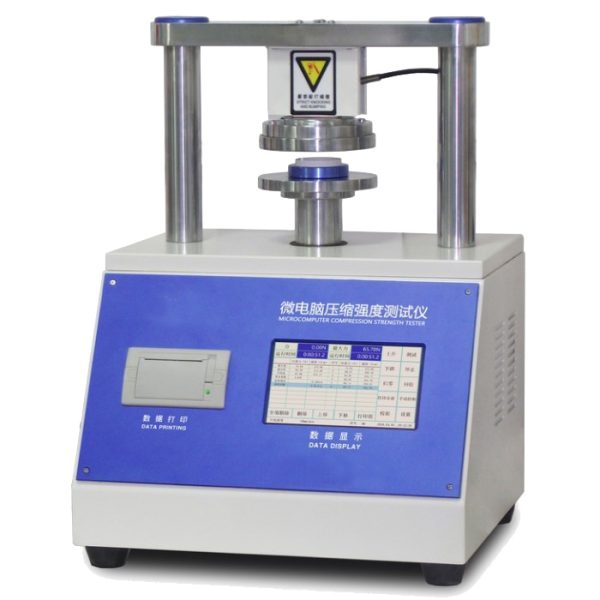

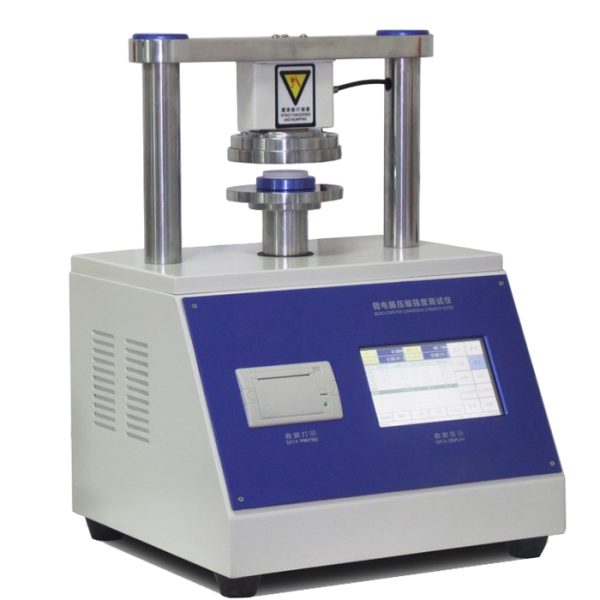

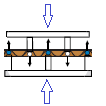

Microcomputer compression strength tester is a touch screen controlled paper and board compression strength tester, which is used to test paper ring pressure strength, cardboard edge pressure strength, corrugated board bonding strength, corrugated board compression strength and so on.Paper mills are usually used to test the RCT of paper with a thickness of 0.15 ~ 1.00mm.Cardboard, carton factories and carton enterprises are commonly used to test corrugated board edge compression strength (ECT), flat compression strength (FCT), bonding strength (PAT) and flat compression strength (CMT) with diameter less than 60mm.This instrument is an ideal auxiliary test tool for paper making enterprises, paperboard manufacturers, carton manufacturers, carton users and quality supervision and inspection departments.

Test standard

GB/T 2679.8 determination of ring compression strength of paper and paperboard(sample area: 152.4×12.7mm)

GB/T 6546 “determination of corrugated board edge pressure strength”;(sample area: 25mm×100mm)

GB/T 6548 “determination of adhesive strength of corrugated board”;(sample area: 25mm×80mm)

GB/T 2679.6 determination of flat compression strength of corrugated base paper;(sample area: 64.5cm2/32.2cm2)

Ring Crush Tester

Specification

Product type:Touched screen control with test curve.

measuring range: 5 ~ 5000N

Edge crush strength:0-50000N/m

Ring crush strength:32.89KN/M

Accuracy:≤1%

Resolution: 0.01 N,0.01kg,0.01LB

test speed: 12.5mm/min

Test Area:Up Down press plate area>100cm2 Height:80mm

Test mode:RCT,ECT,PAT,FCT

Save data:can save 100groups data

Print output:Thermal paper printing output

Outside size:320*300*520mm

Weight:50KG

Function:Data saving and viewing, error data deletion, data printing, parameter setting, equipment calibration, real-time data monitoring, test completion reset, test effect control, limit protection, etc.

Application: carton, paper, corrugated board, color box, plastic hollow board, small carton, small paper tube

Ring Crush Tester

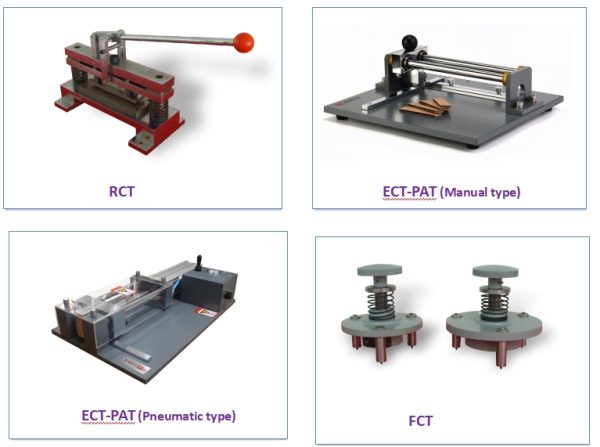

RCT – Ring Crush Test : A sample of paper or cardboard is placed in a ring formation and subjected to a successively increasing edge compression force until it breaks,then the resistance force is measured. The RCT value is the force divided by the sample’s length.

Applicable standards:GB/T2679.8 APPITA/AS 1301.407s, PAPTAC D.33P, DIN 53134, ISO 12192, JIS P8126, SCAN P 34, TAPPI T 822

CLT – Concora Liner Test measures the same way as RCT, but is carried out in another type of sample holder.

CCT – Corrugated Crush Test: A sample is corrugated between heated corrugating rolls. The sample is fixed in a special jig that is adapted to the corrugated shape. The crushing force is applied and measured parallel to the top of the corrugating medium. The CCT value is the maximal force that the sample can withstand before it breaks.

Applicable standards:SCAN P 42, TAPPI T 843

CMT – Concora Medium Test: A sample is corrugated between heated corrugating rolls. The flute is fixed and held together by a pressure-sensitive tape, so that single-sided corrugated board is imitated. The crushing force is applied vertically to the paper ,then the breaking force is measured. The CMT value is the maximal force the sample can withstand before it breaks.

Applicable standards:GB/T2679.6 APPITA/AS 1301.434s, PAPTAC D.24P, DIN 53143, EN ISO 7263, ISO 7263, SCAN P 27, TAPPI T 809

ECT – Edge Crush Test: A sample of corrugated board is subjected to increasing force, parallel to the flutes, until it breaks. The ECT value is the breaking force divided by the sample’s width.

Applicable standards:GB/T6546 APPITA/AS 1301.444s, DIN 53149, EN ISO 3037, FEFCO No.8, ISO 3037, ISO 13821, SCAN P 33, TAPPI T 811, T 823,T 838, T 839

FCT – Flat Crush Test : A sample of corrugated board is subjected to vertical increasing force until the fluting breaks. The FCT value is the force divided by the sample’s surface area.

Flat Crush Hardness – A measurement of the corrugated board’s yield point in a FCT sample. Equivalent to the first ‘peak’.

Flat Crush Energy – The total energy absorbed during a FCT measurement.

Applicable standards:GB/T22874 APPITA/AS 1301.429s, EN 23035, FEFCO No.6, ISO, 3035, SCAN P 32, TAPPI T 825

PAT – Pin Adhesion Test:Adhesion resistance is the maximum force required to separate the linerboard from the fluting with the help of a special sample holder.

Applicable standards:GB/T6548 APPITA/AS 1301.430s, TAPPI T 821

SQT – Score Quality Test:A sample is placed on a U-shaped support and pressed by a thin strip, exactly above a score, until it breaks. The ratio between the scored and un-scored values gives the score ratio.

Applicable standards:TAPPI T 829

CL—Constant Load Test:The test load, speed and time are input to test the deformation of the sample under constant load and specified time.

DL—Deformation Load Test:Input deformation and test speed, test the maximum load of the sample.

attachment

Sample cutter